Did you know a chainsaw comes with different types of chains and each one has its distinct uses? If you’re not careful, and you choose the wrong chainsaw chain types, you’ll make the task more difficult for yourself.

In this article, you’ll get to know all about the different chainsaw types such as full-chisel cutter, semi-chisel cutter, low-profile cutter, full house, and more. Further, you’ll also get to know how you can easily differentiate between them and their uses, so keep on reading.

What are the different chainsaw chain types?

As there are different types of chainsaws available, there are different types of chainsaw chains too. Each type can handle certain tasks quicker than the other due to being engineered for particular purposes. Let’s have a look at the different chainsaw chain types, what makes them different, and their uses.

There are different types of chainsaw chains as they come in specific variations –

- Cutter type

- Chain sequence/arrangement

Let’s examine each one of these chainsaw categories and the different chainsaw chain types they comprise.

Cutter type

This category is defined by the “shape” of the chain as it represents the angle of the chain’s cutter blades. Over the years, chainsaw manufacturers have designed the chainsaw chains to cut faster and easier. This category consists of five types of chainsaw chains.

- Full-chisel cutter

- Semi-chisel cutter

- Low-profile chain

- Narrow kerf chain

- Ripping chain

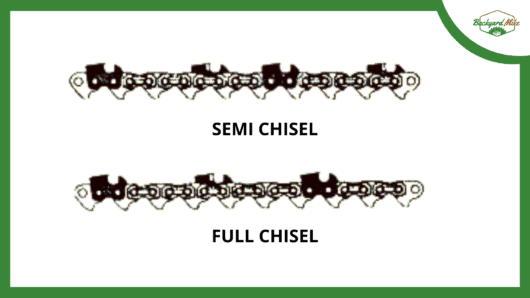

Full-chisel cutters

The full-chisel cutter chain type will feature square-cornered teeth, making them extremely efficient for cutting at high speeds. This kind of chain is best for cutting hardwoods if the smoothness of the cut is not paramount. Further, this chainsaw type will excel at cutting trees, branches, limbs, and cutting firewood.

Although the full-chisel cutter is an efficient chainsaw chain type, it comes with its own noteworthy drawback. First off, a full-chisel cutter isn’t the most durable chain type. Further, it cannot withstand rough-cutting environments like dirty wood. There is also a greater risk of chainsaw kickback due to the fact that this type of chain operates at higher speeds. As a result, it doesn’t utilize the safety elements that other types of chain feature. Also, it doesn’t make clean cuts, which makes it isn’t the ideal option to use with softwoods.

Semi-chisel cutters

Semi-chisel cutters come with teeth having rounded corners. These chains will operate at slower speeds as compared to the full-chisel cutters. This is why semi-chisel chains excel at cutting softwoods. They can also be used for cutting in rough environments like dirty, frozen, or dry woods.

While a semi-chisel cutter lacks speed, it will make up for that by its reliability. Unlike full-chisel chains, the semi-chisel cutter is far more durable. Further, it can easily handle rough environments, making it desirable for tackling different types of wood. It also has a lower risk of kickback. Safety is an important issue when dealing with chainsaws on a regular basis, and you will likely enjoy having a chain that prevents kickback from occurring. Especially when considering the fact that yearly there are over 36,000 chainsaw accidents with kickback being the most common cause.

Low-profile cutter

The Low-profile or lo-pro chain features cutters that aren’t as tall as most other chainsaw chains. This means that this kind of chain makes comparatively shallow cuts. The biggest advantage of using a low-profile chain is that it weighs far less than standard chains. This makes low-profile chains a better fit for electric saws or low-horsepower saws. Having a lighter weight will mean that less strain is being put on the engine.

Low profile chain generally comes in a 3/8-inch pitch and a 0.050-inch gauge. However, you should keep in mind that if your chainsaw uses a bar that requires over 72 drive links on the chain, a low-profile chain won’t work with the bar and chainsaw.

Narrow kerf chain

Similar to low-profile chains having shorter cutters than standard chains, narrow kerf chains will have narrower cutters than standard chains. If you’re using a narrow kerf chain, you should expect to get cuts that are thinner and narrower than normal.

As the cuts are thinner, a narrow kerf chain will ultimately cut less wood as compared to standard chains when cutting. However, it’ll also allow your chainsaw to cut more quickly. You can even use a long bar with a full-size chain with a low-horsepower chainsaw. Narrow kerf chains are usually the preferred choice for electric chainsaws.

You should always check the compatibility of the narrow kerf chain with the bar and your chainsaw. Your bar needs to be designated as a bar that is designed to fit a narrow kerf chain. Some narrow kerf chains even qualify as low-profile chains that offer the ultimate high-speed, lightweight cutting experience.

Ripping chain

Both low-profile and narrow kerf chains will help you use the chainsaw very efficiently for standard tasks. You can easily prune tree limbs, cut branches, fell trees, trim the bushes, and more. In contrast, ripping chains are designed for one specific task – milling tree logs into planks of wood.

The cutters on a ripping chain tend to cut at an angle lower than those on standard chainsaws. Normally, it is 10 degrees versus the standard 30 degrees. Further, ripping chains will also cut along the wood’s grain instead of cutting against it.

As a result, ripping chains will remove smaller chunks of wood and will be less aggressive, despite what the name suggests. This will make ripping chains a better option for creating fine cuts and smooth planks, while also explaining the high prices. A ripping chain is a perfect option if you’re looking to use a portable sawmill with your chainsaw for milling lumber.

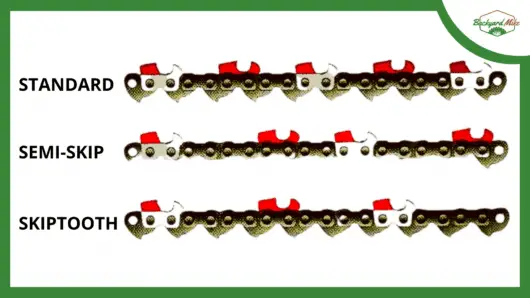

Chain sequence/arrangement

The chain sequence or arrangement defines the spacing between the teeth or cutters in the chain. It is important to note that it is different from the pitch of the chain. Pitch is used to tell the difference between the links, and not all links feature a cutter. The chain’s sequence will be the distance between the chain’s cutters.

There are three main types of chainsaw chain types when going by the chain sequence or arrangement.

- Full-skip

- Semi-skip

- Standard/full house

Each one of these chain sequences is used for different tasks. Chain arrangement will make the difference when it comes to the safety of operation and how the chainsaw is cutting. Let’s have a look at the different chainsaw chain types in terms of arrangements.

Full-skip chain

This type of chain arrangement is highly efficient for cutting. In a full-skip chain, there are fewer teeth , but the bar is comparatively larger (24 inches or more). Sometimes people think that fewer teeth would mean less cutting power, however, it isn’t the case. In fact, this arrangement of teeth results in faster operational speed and allows you to cut larger portions of wood.

While the full-skip chain can cut faster, the cuts it makes will not be as smooth. It is highly efficient when it comes to cutting limbs, firewood, and other tasks in which smoothness can be overlooked. Moreover, it is worth noting that this type of chain is perfect for larger chainsaws. Due to the arrangement of the teeth and the larger bar, a smaller chainsaw will not be practical.

Semi-skip chain

The semi-skin chain is essentially a mid-grade chainsaw chain arrangement. The teeth in this one are arranged where there are 1-2 links between the cutters. Unlike full-skip chains, a semi-skip chain cannot cut through wood as quickly. However, it is still a powerful chain in its own right.

This type of chain is preferred by professionals who want a semi-skip chain for specific jobs. Although it doesn’t cut as fast as the full-skip, it’ll still offer a solid balance between efficiency and power. Further, it’ll do that with much smoother cuts.

Standard/Full house

The standard or full house chain features the most teeth among the three, making it the best for smooth cuts. A full house or standard chain is a full-skip chain placed on a larger bar. This kind of chain is used on chainsaws featuring a guide bar that is up to 24 inches.

The downside of standard/full house chains is that they don’t cut wood as quickly when compared to full-skip or semi-skip. However, they are highly efficient in terms of the type of cuts they make. A full house chain is best suited for any situation that requires clean finishes, like when cutting timber for buildings.

Conclusion

When purchasing a new chainsaw chain, you may be tempted to go for the most powerful, fastest, or expensive options. However, you shouldn’t pay an exceeding amount of money for the wrong type of chains that you don’t even need. Instead, you should think of the size of your chainsaw, the type of tasks you have to do, the smoothness you want, and other factors.

After all, there is no use in buying a chainsaw chain that costs a lot but isn’t able to help you do the tasks at hand. Hopefully, this article would have given you enough information about the different chainsaw chain types. There are several options available, but you should concentrate on the one that best fits your needs. Picking the right chainsaw chain can be a bit tricky if you’re not sure of what you’re after. This article will help you know which type of chainsaw you should be after. Lastly, remember to prioritize your safety. Whenever handling sharp objects like a chainsaw chain, make sure that you wear the proper safety equipment.